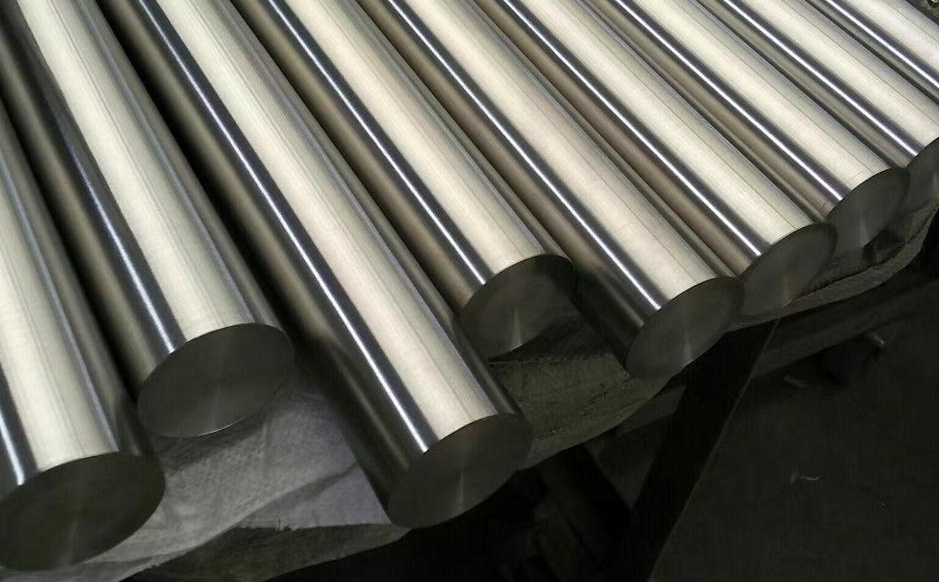

NITRONIC 50 (XM-19/FXM-19) S20910 stainless steel,

Nitronic 50 is a type of material widely referred to as XM-19, which is the designation of the generic alloy caption in ASTM A182, ASTM A276 and ASTM A479, as well as UNS S20910

Nitronic 50 (XM-19/FXM-19) S20910 is a nitrogen-strengthened austenitic stainless steel with better corrosion resistance than 316, 616L, 317 and 317L, And the yield strength at room temperature is almost twice the yielding strength than the regular 3xx series stainless steel. This material has very good mechanical properties at high and sub-zero temperatures. S20910 can maintain very low permeability even after large cold deformation or at sub-zero temperature, and has very good mechanical properties at 1200¡ãF (649¡ãC). Although S20910 can maintain a very low permeability in a low temperature environment, it still cannot reach the level of Nitronic 33 and Nitronic 40. S20910 has demonstrated outstanding corrosion resistance in many processes. After annealing at 2025¡ãF (1107¡ãC), S20910 can exhibit excellent corrosion resistance even after welding. This steel has outstanding performance in resistance to sulfide stress corrosion cracking and resistance to intergranular corrosion. S20910 can withstand long-term exposure to the marine atmosphere. Tests have shown that its corrosion resistance in calm sea water is slightly better than Monel 400 (UNS N04400). This steel is affected by stress corrosion cracking in a nitride environment, and its crack resistance is between 304 and 316. It is a high-efficiency alloy used in petroleum, petrochemical, chemical, fertilizer, nuclear fuel recycling, pulp and paper, textile, food processing and marine industries. Use highly corrosion-resistant and high-strength NITRONICS 50 stainless steel components, including pumps, valves and accessories, fasteners, cables, chains, screens and wire coats, marine hardware such as boats, pump shafts, heat exchangers, springs and photography equipment.

Product Benefits

-

Outstanding corrosion resistance

-

Superior mechanical performance

-

Easily welded

-

Does not become magnetic when cold formed

-

Excellent resistance to intergranular attack

-

Good mechanical properties in both high and sub-zero temperature service

-

Exceptionally low magnetic permeability

-

Double the yield strength of 304 and 316 stainless steel

|

Elements

|

Composition limits %

|

|

Carbon

|

C

|

̼

|

0.06max

|

|

Manganese

|

Mn

|

ÃÌ

|

4.0-6.0

|

|

Phosphorus

|

P

|

Á×

|

0.045 max

|

|

Sulfur

|

S

|

Áò

|

0.030 max

|

|

Silicon

|

Si

|

¹è

|

1.00 max

|

|

Chromium

|

Cr

|

¸õ

|

20.5-23.5

|

|

Nickle

|

Ni

|

Äø

|

11.5-13.5

|

|

Nitrogen

|

N

|

µª

|

0.20-0.40

|

|

Molybdenum

|

Mo

|

îâ

|

1.5-3.00

|

|

Columbium

|

Cb

|

îê

|

0.10-0.30

|

|

Vanadium

|

V

|

·°

|

0.10-0.30

|

|

Status

|

Tensile Strength

|

Yielding Strength

|

Elongation

|

Hardness

|

|

|

Rm N/mm2

|

Rp N/mm2

|

A5%

|

HB

|

|

Solution Annealed

|

690

|

380

|

35

|

¡Ü241

|

|