Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high temperature applications where aluminum and steel would succumb to creep as a result of thermally induced crystal vacancies. Inconel¡¯s high temperature strength is developed by solid solution strengthening or precipitation strengthening, depending on the alloy.

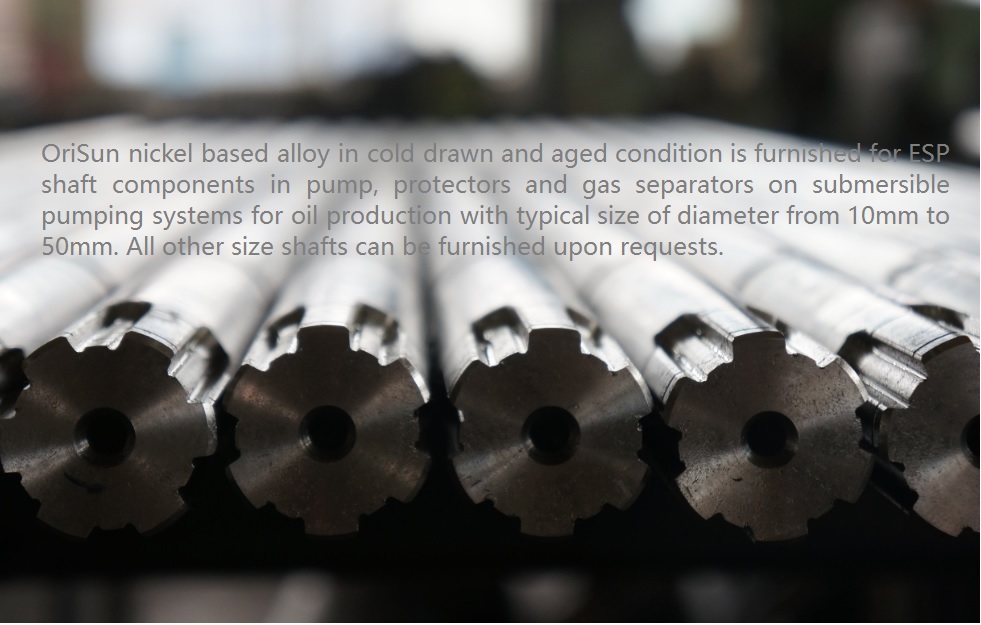

OriSun Co Ltd. stocks Inconel 718 in a range of sizes including 10-50mm diameter cold drawn, annealed and aged, and 50-100mm diameter hot finished and aged. Material can be supplied in random lengths, cut to order or machined to your specifications. Machining includes drilling, turning, tapping, threading, CNC shapes, flanges and more.

Applicable Standard:

ASTM B637 Standard Specification for Precipitation-Hardening and Cold Worked Nickel Alloy Bars, Forgings, and Forging Stock for Moderate or High Temperature Service

|

Typical Composition: |

|

|

Element (% by mass) |

|

Element |

Content |

|

Ni (Nickel). |

50.00~55.00 |

|

Cr (Chromium). |

17.00~21.00 |

|

Nb +Ta ( Niobium+Tantalum |

4.75~5.5 |

|

Mo (Molybdenum) |

2.80~3.30 |

|

Ti (Titanium) |

0.65~1.15 |

|

Al (Aluminum) |

0.20~0.80 |

|

Co (Conalt) |

<1.00 |

|

C (Carbon) |

<0.08 |

|

Mn (Manganese) |

<0.35 |

|

Si (Silicon) |

<0.35 |

|

P (Phosphorus) |

<0.015 |

|

S (Sulfer) |

<2 |

|

B (Boron) |

<0.006 |

|

Cu (Copper) |

<0.30 |

|

Fe (Iron) |

Balance |

|

|

|

|

Mechanical Properties |

|

Properties |

min |

|

Tensile Strength |

>185 ksi |

|

Yielding Strength |

>150 ksi |

|

Elongation |

>12% |

|

Hardness |

>331 HB |

|

|